Categories

-

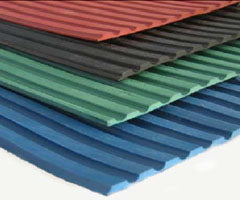

Rubber Flooring

-

Rubber Matting

-

Rubber Sheet

-

Rubber Mats

-

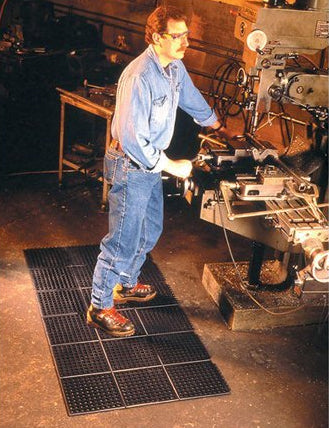

Industrial Mats

Industrial Mats

-

Rubber Grass Mats

Rubber Grass Mats

-

Industrial Floor Mats

Industrial Floor Mats

-

Horse Mats And Stable Mats

Horse Mats And Stable Mats

-

Kitchen Mats

Kitchen Mats

-

Playground Safety Mats

Playground Safety Mats

-

Gym Mats

Gym Mats

-

Anti Fatigue Mats

Anti Fatigue Mats

-

Anti Slip Mats

Anti Slip Mats

-

Grass Mats / Walkway Mats

Grass Mats / Walkway Mats

-

Playground Mats

Playground Mats

-

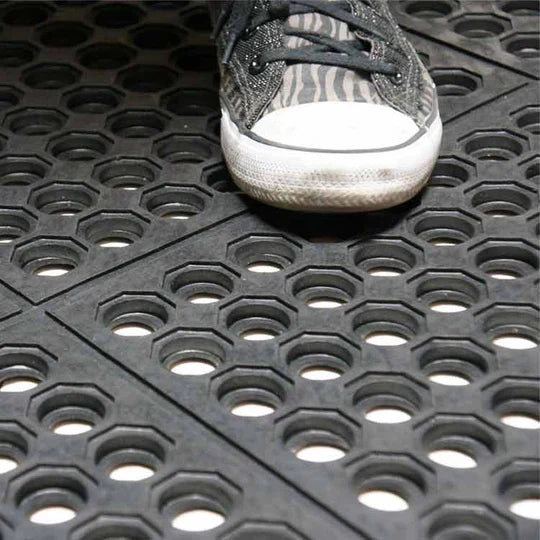

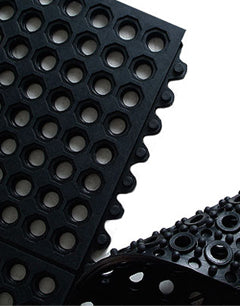

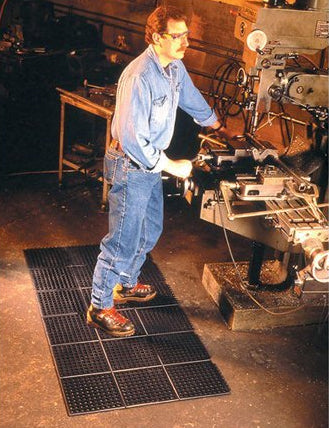

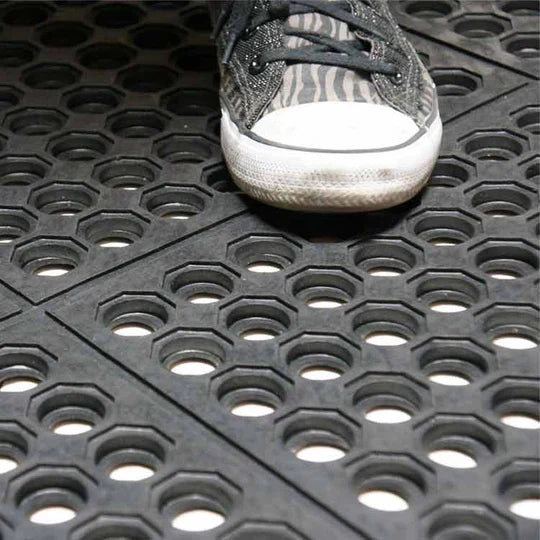

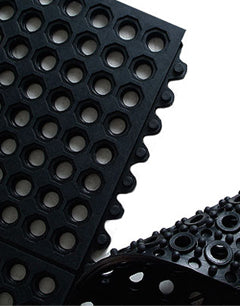

Anti-Fatigue/Anti-Slip Wet Area Mats

Anti-Fatigue/Anti-Slip Wet Area Mats

-

Premium Rubber Grass Mats

Premium Rubber Grass Mats

-

Rubber Gym Mats - Gym Flooring

Rubber Gym Mats - Gym Flooring

-

Rubber Floor Tiles

Rubber Floor Tiles

-

Horticultural and Ground Reinforcement

Horticultural and Ground Reinforcement

-

Industrial Safety Mats

Industrial Safety Mats

-

Workshop Mats

Workshop Mats

-

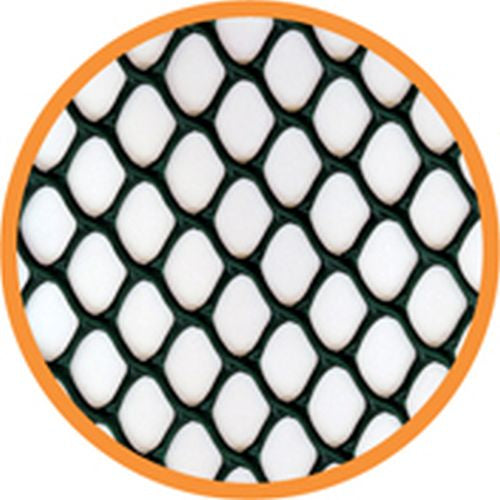

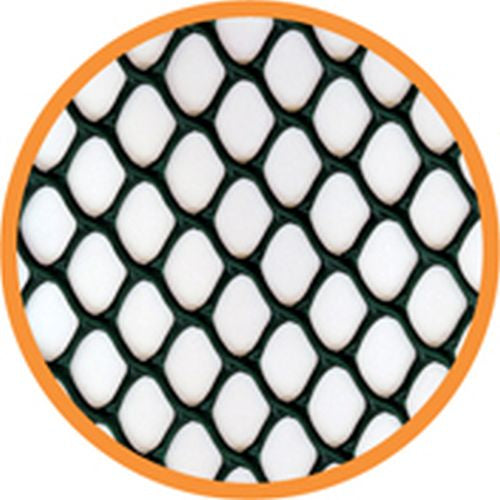

Ground Protection Mesh

Ground Protection Mesh

-

Acoustic Tiles

Acoustic Tiles

-

-

Stair Nosings

-

Industrial Products

-

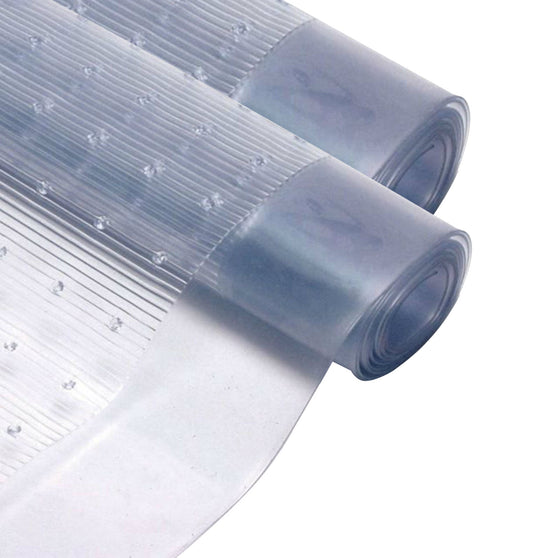

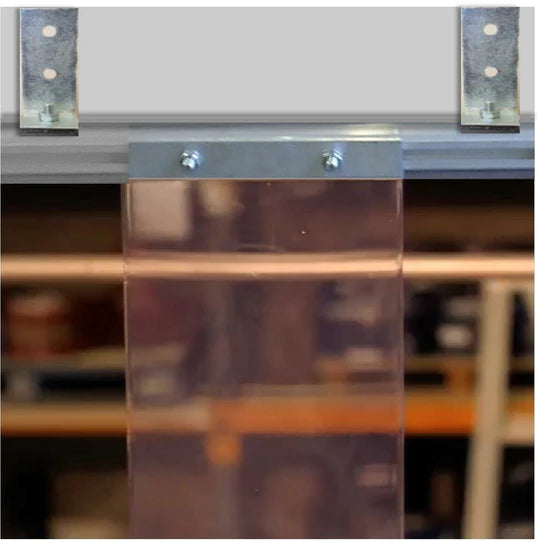

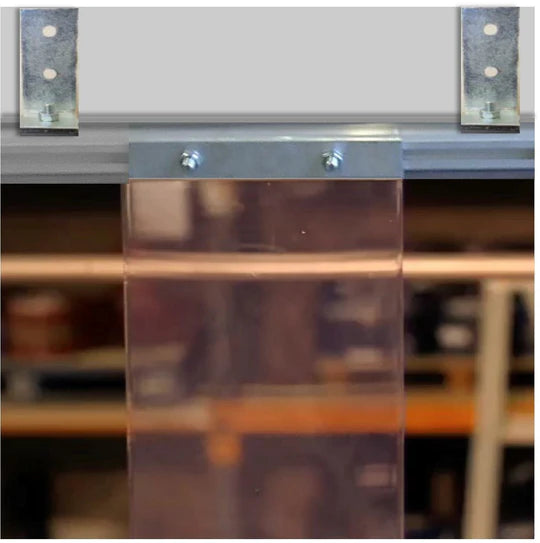

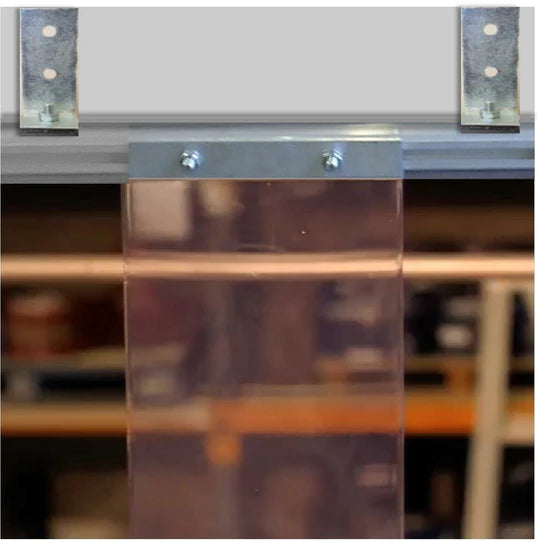

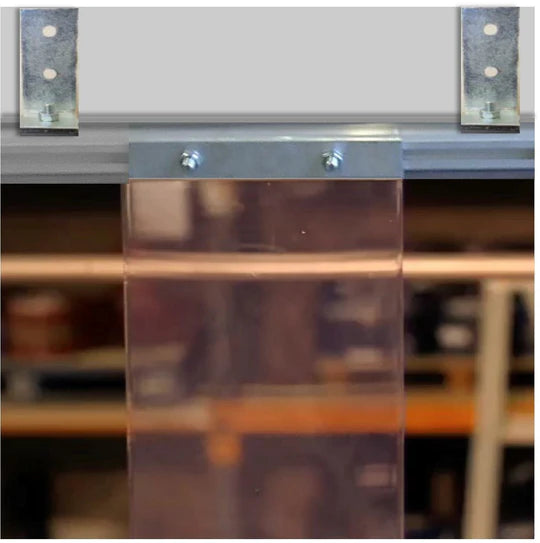

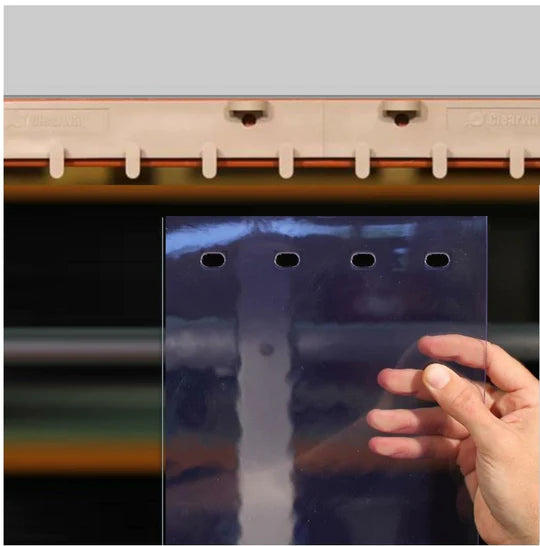

Pvc Strip Curtains

-

Pedestrian PVC strip curtains

Pedestrian PVC strip curtains

-

Food & catering PVC strip curtains

Food & catering PVC strip curtains

-

Commercial PVC strip curtains

Commercial PVC strip curtains

-

Industrial PVC strip curtains

Industrial PVC strip curtains

-

Pest control strip curtains & brushstrip

Pest control strip curtains & brushstrip

-

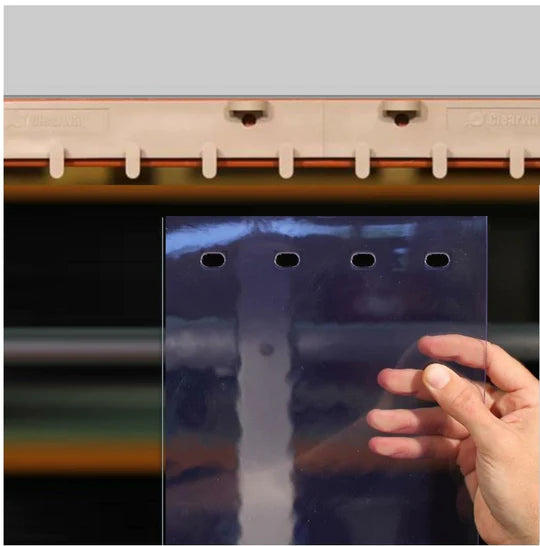

Hook on PVC curtain strips

Hook on PVC curtain strips

-

Swivel hinge PVC curtain strips

Swivel hinge PVC curtain strips

-

Twin track PVC curtain strips

Twin track PVC curtain strips

-

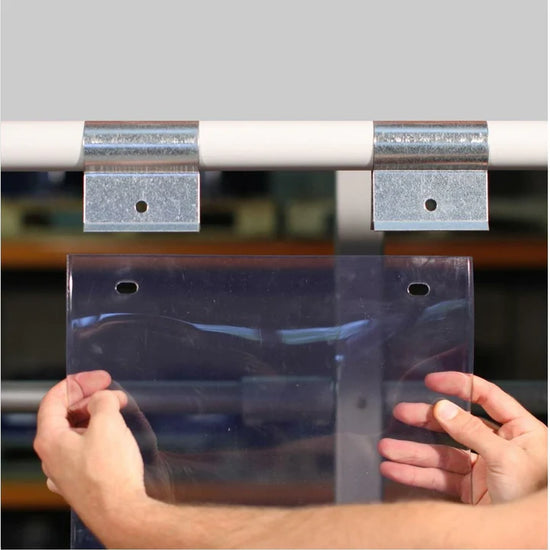

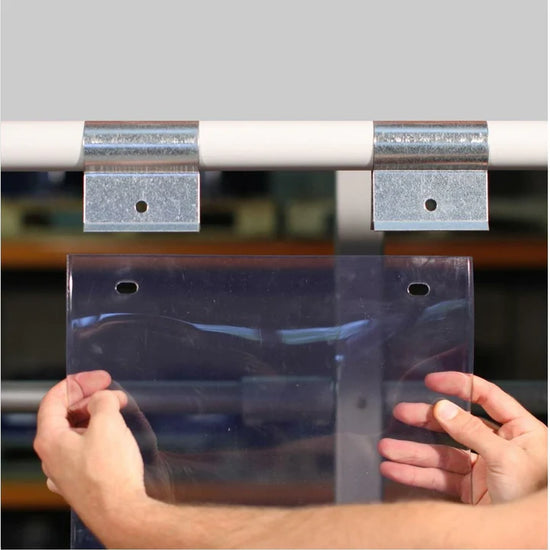

QuickMount PVC curtain strips

QuickMount PVC curtain strips

-

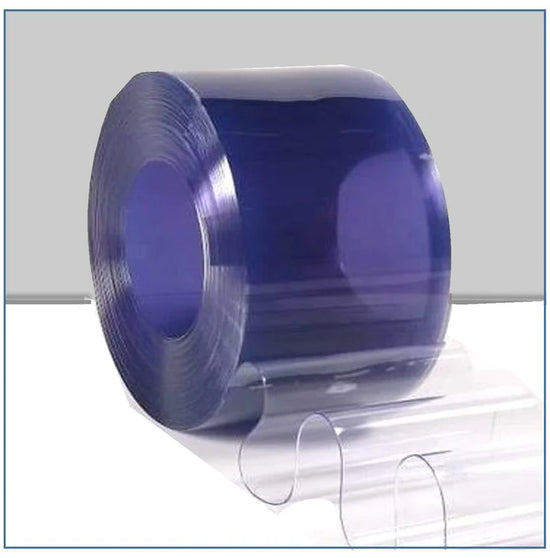

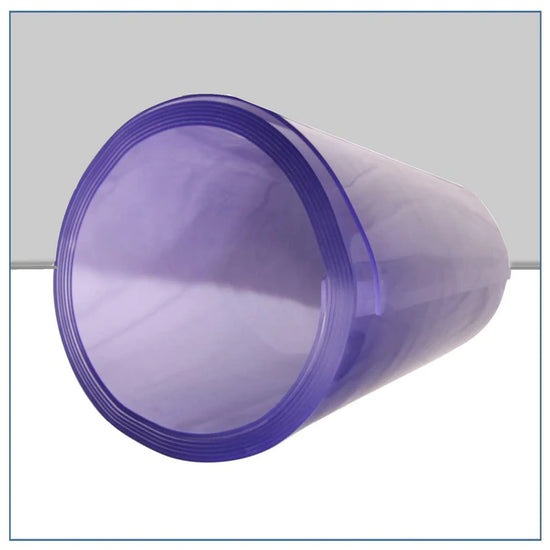

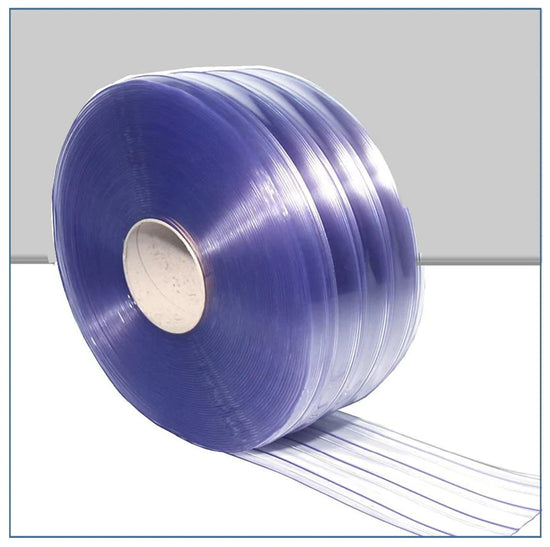

Blank Pvc Strip By Metre

Blank Pvc Strip By Metre

-

PVC sheet by the metre

PVC sheet by the metre

-

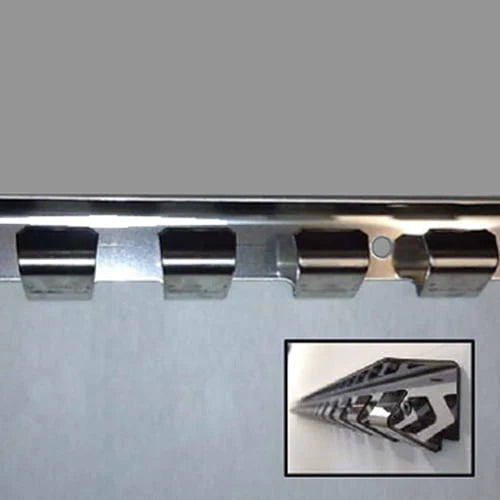

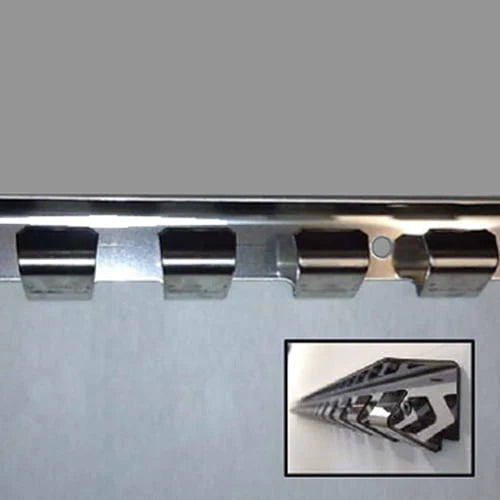

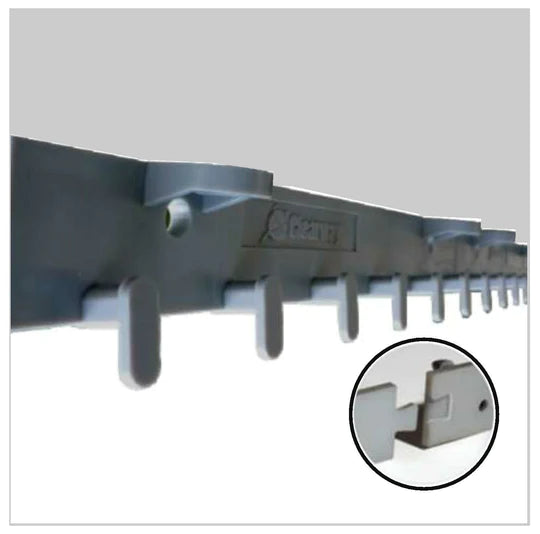

Hook On Rails

Hook On Rails

-

Swivel Hinge Rails

Swivel Hinge Rails

-

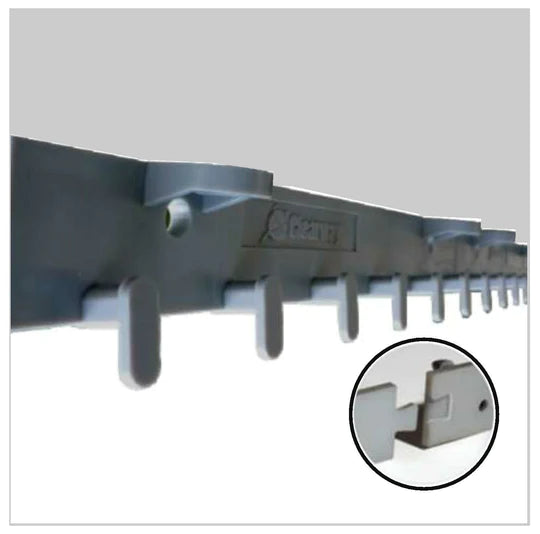

Twin Track Rails

Twin Track Rails

-

Quick Mount Rails

Quick Mount Rails

-

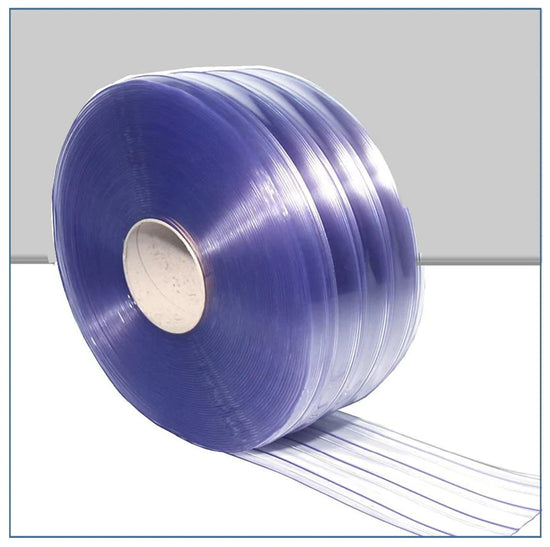

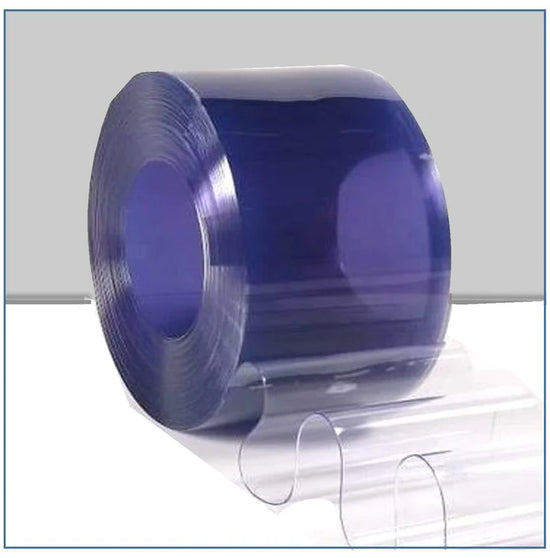

PVC Rolls

PVC Rolls

-

-

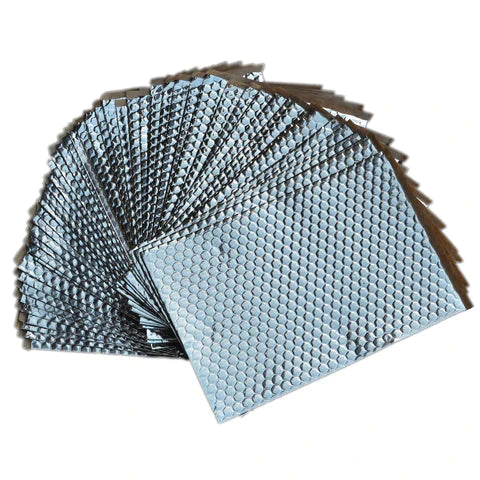

Sound Deadening

-

Insulations

Our Clients

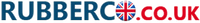

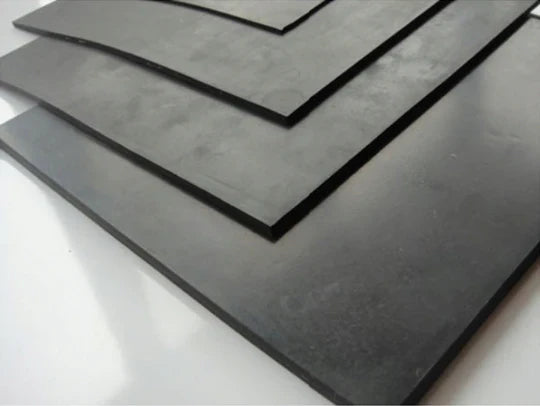

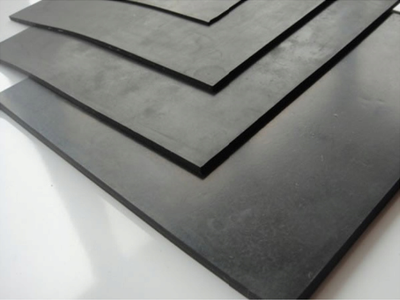

Commercial Grade Nitrile Rubber Sheet (NBR)

Superior oil resistance for automotive, industrial, and petroleum applications

Technical Specification

Engineered for Oil & Fuel Resistance

Our commercial-grade nitrile rubber sheet (NBR) represents the industry standard for applications requiring exceptional resistance to petroleum oils, fuels, and hydrocarbon-based fluids. Meticulously engineered from acrylonitrile-butadiene copolymer, this high-performance elastomer delivers reliable sealing and protection in the most demanding automotive, industrial, and petroleum environments.

Unlike natural rubber or EPDM compounds that degrade rapidly when exposed to mineral oils, nitrile rubber maintains its physical properties, dimensional stability, and sealing integrity even under continuous petroleum exposure. This makes NBR the material of choice for fuel systems, hydraulic seals, oil-handling equipment, and any application where hydrocarbon resistance is critical.

Chemical & Fluid Resistance

- Excellent Resistance — Petroleum oils, mineral oils, hydraulic fluids, diesel fuel, petrol, kerosene

- Good Resistance — Aliphatic hydrocarbons, vegetable oils, animal fats, silicone oils, greases

- Moderate Resistance — Dilute acids, dilute alkalis, water (short-term exposure)

- Poor Resistance — Aromatic hydrocarbons (benzene, toluene), ketones, ozone, strong acids

- Alternative Materials — Specify EPDM for ozone/weather resistance, neoprene for balanced properties

Applications & Industries

Automotive & Transport

Fuel system gaskets, oil seals, hydraulic hoses, transmission seals, engine bay components

Petroleum & Oil Industry

Tank liners, pump seals, pipeline gaskets, fuel storage containment, oil-handling equipment

Hydraulic Systems

Cylinder seals, O-rings, hydraulic pump gaskets, pressure vessel seals, fluid power systems

Industrial Manufacturing

Machine gaskets, oil-resistant conveyor belts, protective padding, workshop bench liners

Why Specify Nitrile Rubber (NBR)?

Nitrile rubber's unique molecular structure provides unmatched resistance to petroleum-based oils and fuels—properties that natural rubber, EPDM, and silicone cannot deliver. The acrylonitrile content (typically 18-50%) determines oil resistance: higher acrylonitrile grades offer superior oil resistance but reduced low-temperature flexibility. Our commercial-grade NBR balances excellent oil resistance with good mechanical properties and cost-effectiveness, making it the industry standard for automotive, hydraulic, and petroleum applications.

Material Properties

| Property | Value |

|---|---|

| Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥ 12 MPa |

| Elongation at Break | ≥ 300% |

| Specific Gravity | 1.20 – 1.25 |

| Temperature Range | -30°C to +100°C (continuous) |

| Abrasion Resistance | Excellent |

| Compression Set (22h @ 70°C) | ≤ 30% |

| Oil Swell (ASTM Oil No. 3, 70h @ 100°C) | ≤ 25% volume increase |

Performance Advantages

✓ Superior Oil Resistance

Maintains integrity in continuous petroleum oil exposure where other elastomers fail

✓ Excellent Abrasion Resistance

Withstands mechanical wear in high-friction applications and dynamic sealing

✓ Good Tensile Strength

High tear resistance and mechanical durability for demanding industrial use

✓ Wide Temperature Range

Performs reliably from -30°C to +100°C in automotive and industrial environments

✓ Low Gas Permeability

Excellent barrier properties for fuel systems and gas containment applications

✓ Cost-Effective Solution

Industry-standard material offering optimal balance of performance and value

Ordering Information

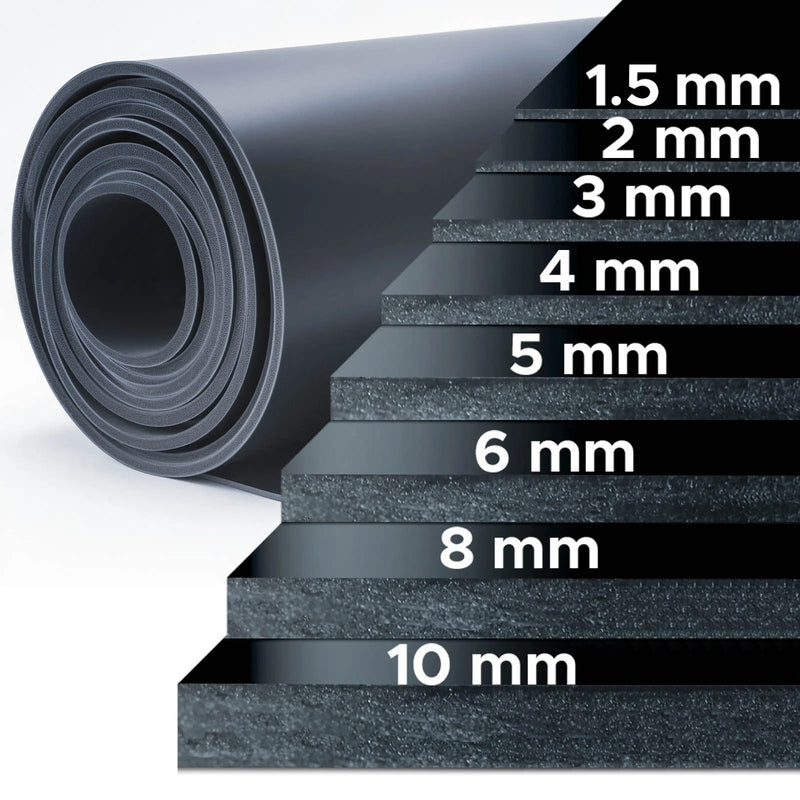

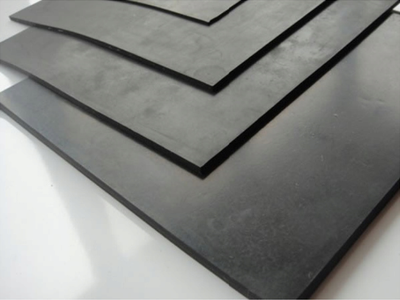

Available Thicknesses: 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm

Sheet Width: 1.4 metres (standard)

Pricing: Per linear metre (1.4m² per metre)

Colour: Black (standard)

Roll Length: Typically 10 metres (full rolls available)

UK stock held for rapid dispatch. Custom thicknesses, full roll pricing, and die-cutting services available on request. For outdoor/weather applications, please specify EPDM or neoprene rubber.

Fabrication & Installation

Nitrile rubber sheet can be easily cut, punched, and fabricated using standard workshop tools. Sharp utility knives, die-cutting presses, and water-jet cutting all produce clean edges. The material bonds well with nitrile-compatible contact adhesives and can be vulcanized for permanent joints in critical sealing applications.

Gasket Fabrication: Ideal for custom gasket cutting using templates, CNC cutting, or manual fabrication. Maintains dimensional stability and sealing force under compression.

Typical Lead Time: Cut-to-length orders dispatched within 3-5 working days. Custom die-cutting, gasket fabrication, and large-volume orders available with project-specific lead times.

Technical Support & Project Assistance

Our technical team provides complimentary material selection guidance, chemical compatibility verification, thickness recommendations, and custom fabrication quotes for automotive, hydraulic, and industrial projects. Contact us for project-specific advice, bulk pricing, and die-cutting services.

About Us

All orders ship quickly for free via  &

&

We are a UK company with over 60 years of experience in the industry.

Your orders support a family owned and operated business.

-

FREE Shipping anywhere in the UK

FREE Shipping anywhere in the UK

-

Satisfaction Guaranteed.

Satisfaction Guaranteed.

-

Secure Payments

Secure Payments

-

Need help? Call Us 01282 277786 or email

sales@rubberco.co.uk

Need help? Call Us 01282 277786 or email

sales@rubberco.co.uk

- In stock

Our Clients

Commercial Grade Nitrile Rubber Sheet (NBR)

Superior oil resistance for automotive, industrial, and petroleum applications

Technical Specification

Engineered for Oil & Fuel Resistance

Our commercial-grade nitrile rubber sheet (NBR) represents the industry standard for applications requiring exceptional resistance to petroleum oils, fuels, and hydrocarbon-based fluids. Meticulously engineered from acrylonitrile-butadiene copolymer, this high-performance elastomer delivers reliable sealing and protection in the most demanding automotive, industrial, and petroleum environments.

Unlike natural rubber or EPDM compounds that degrade rapidly when exposed to mineral oils, nitrile rubber maintains its physical properties, dimensional stability, and sealing integrity even under continuous petroleum exposure. This makes NBR the material of choice for fuel systems, hydraulic seals, oil-handling equipment, and any application where hydrocarbon resistance is critical.

Chemical & Fluid Resistance

- Excellent Resistance — Petroleum oils, mineral oils, hydraulic fluids, diesel fuel, petrol, kerosene

- Good Resistance — Aliphatic hydrocarbons, vegetable oils, animal fats, silicone oils, greases

- Moderate Resistance — Dilute acids, dilute alkalis, water (short-term exposure)

- Poor Resistance — Aromatic hydrocarbons (benzene, toluene), ketones, ozone, strong acids

- Alternative Materials — Specify EPDM for ozone/weather resistance, neoprene for balanced properties

Applications & Industries

Automotive & Transport

Fuel system gaskets, oil seals, hydraulic hoses, transmission seals, engine bay components

Petroleum & Oil Industry

Tank liners, pump seals, pipeline gaskets, fuel storage containment, oil-handling equipment

Hydraulic Systems

Cylinder seals, O-rings, hydraulic pump gaskets, pressure vessel seals, fluid power systems

Industrial Manufacturing

Machine gaskets, oil-resistant conveyor belts, protective padding, workshop bench liners

Why Specify Nitrile Rubber (NBR)?

Nitrile rubber's unique molecular structure provides unmatched resistance to petroleum-based oils and fuels—properties that natural rubber, EPDM, and silicone cannot deliver. The acrylonitrile content (typically 18-50%) determines oil resistance: higher acrylonitrile grades offer superior oil resistance but reduced low-temperature flexibility. Our commercial-grade NBR balances excellent oil resistance with good mechanical properties and cost-effectiveness, making it the industry standard for automotive, hydraulic, and petroleum applications.

Material Properties

| Property | Value |

|---|---|

| Hardness (Shore A) | 60 ± 5 |

| Tensile Strength | ≥ 12 MPa |

| Elongation at Break | ≥ 300% |

| Specific Gravity | 1.20 – 1.25 |

| Temperature Range | -30°C to +100°C (continuous) |

| Abrasion Resistance | Excellent |

| Compression Set (22h @ 70°C) | ≤ 30% |

| Oil Swell (ASTM Oil No. 3, 70h @ 100°C) | ≤ 25% volume increase |

Performance Advantages

✓ Superior Oil Resistance

Maintains integrity in continuous petroleum oil exposure where other elastomers fail

✓ Excellent Abrasion Resistance

Withstands mechanical wear in high-friction applications and dynamic sealing

✓ Good Tensile Strength

High tear resistance and mechanical durability for demanding industrial use

✓ Wide Temperature Range

Performs reliably from -30°C to +100°C in automotive and industrial environments

✓ Low Gas Permeability

Excellent barrier properties for fuel systems and gas containment applications

✓ Cost-Effective Solution

Industry-standard material offering optimal balance of performance and value

Ordering Information

Available Thicknesses: 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm

Sheet Width: 1.4 metres (standard)

Pricing: Per linear metre (1.4m² per metre)

Colour: Black (standard)

Roll Length: Typically 10 metres (full rolls available)

UK stock held for rapid dispatch. Custom thicknesses, full roll pricing, and die-cutting services available on request. For outdoor/weather applications, please specify EPDM or neoprene rubber.

Fabrication & Installation

Nitrile rubber sheet can be easily cut, punched, and fabricated using standard workshop tools. Sharp utility knives, die-cutting presses, and water-jet cutting all produce clean edges. The material bonds well with nitrile-compatible contact adhesives and can be vulcanized for permanent joints in critical sealing applications.

Gasket Fabrication: Ideal for custom gasket cutting using templates, CNC cutting, or manual fabrication. Maintains dimensional stability and sealing force under compression.

Typical Lead Time: Cut-to-length orders dispatched within 3-5 working days. Custom die-cutting, gasket fabrication, and large-volume orders available with project-specific lead times.

Technical Support & Project Assistance

Our technical team provides complimentary material selection guidance, chemical compatibility verification, thickness recommendations, and custom fabrication quotes for automotive, hydraulic, and industrial projects. Contact us for project-specific advice, bulk pricing, and die-cutting services.

About Us

All orders ship quickly for free via  &

&

We are a UK company with over 60 years of experience in the industry.

Your orders support a family owned and operated business.

Commercial Grade Nitrile Rubber Sheet – NBR Oil Resistant | 1.5-25mm | 1.4m Wide | Per Metre

X Commercial Grade Nitrile Rubber Sheet – NBR Oil Resistant | 1.5-25mm | 1.4m Wide | Per Metre Added To Cart.

- Free Shipping.

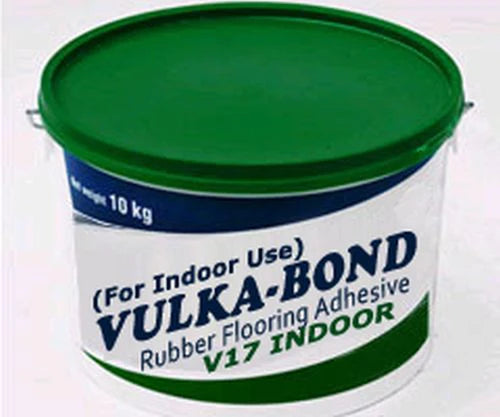

Frequently Bought Together...

Our Clients